Pallet flow racks, also commonly referred to as Flow-Through Rack or Gravity Flow Rack, represents an advanced storage solution designed to optimize warehouse efficiency and streamline material handling processes. Here's an introduction to this innovative storage system in English:

Pallet flow racks: An Overview

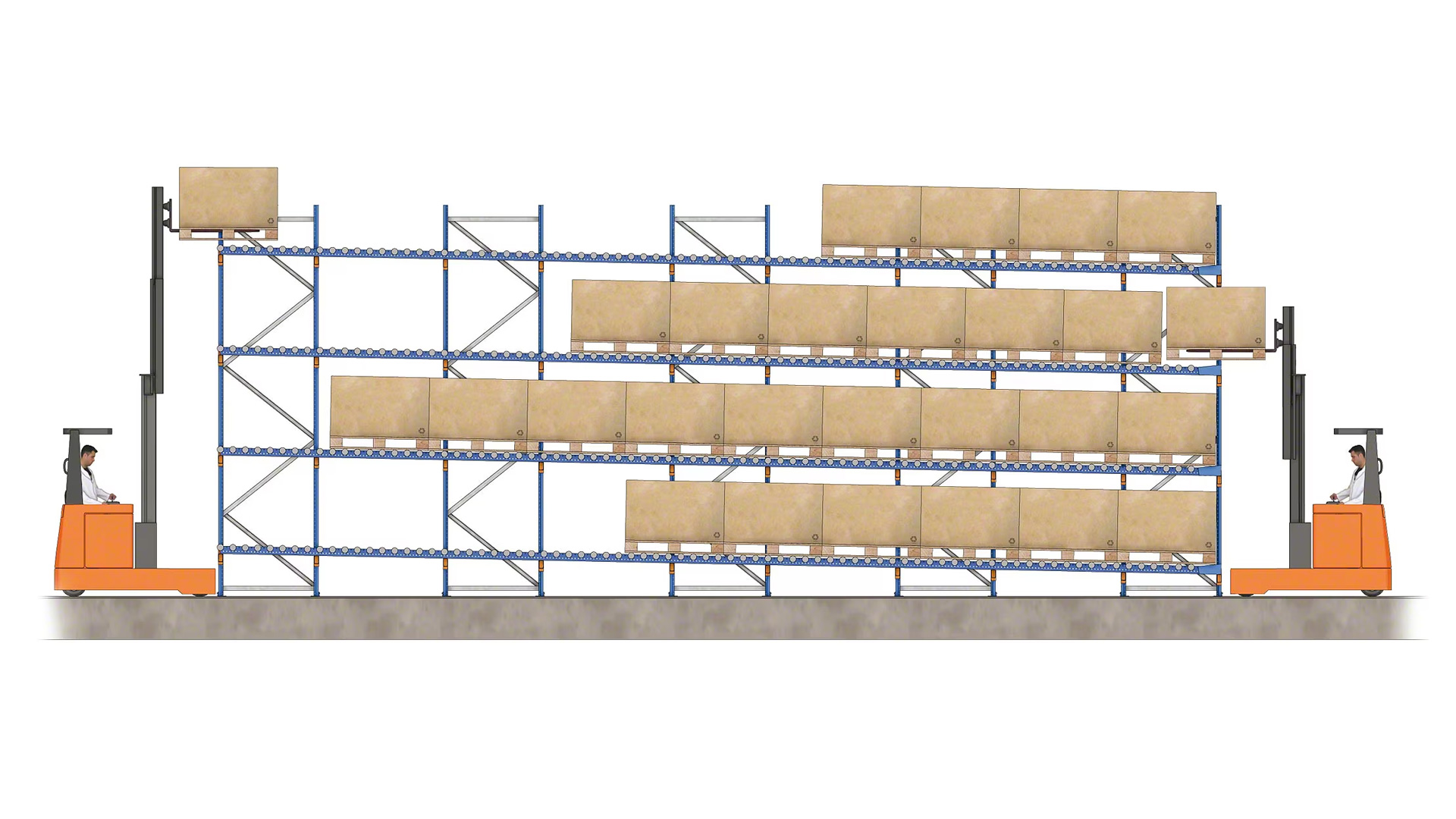

Pallet flow racks is a dynamic storage system characterized by its ability to facilitate the first-in, first-out (FIFO) inventory management principle. Utilizing the force of gravity, items are loaded at one end of the rack and automatically flow to the discharge end, making it ideal for high-turnover products that require quick access and continuous replenishment.

Key Features and Advantages

-

Efficiency: The smooth flow of products eliminates the need for manual retrieval, significantly reducing labor costs and enhancing operational efficiency.

-

Space Optimization: Pallet flow racks maximize warehouse space by utilizing vertical storage and minimizing aisle space, as products are accessed from the same lane.

-

Inventory Management: The FIFO system ensures that older inventory is utilized first, reducing the risk of obsolescence and improving stock rotation.

-

Scalability: These racks can be configured to accommodate various product sizes and weights, and they can be easily expanded or modified to fit changing business needs.

-

Accessibility: With products continuously moving towards the discharge end, picking times are minimized, and accessibility is maximized, particularly in high-demand environments.

Design and Operation

Pallet flow racks are typically constructed with inclined roller conveyors or sliding tracks that allow products to move down the rack under their own weight or with minimal assistance from gravity. The angle of inclination is carefully calculated to ensure a controlled and steady flow of products without causing damage.

The racks are usually divided into lanes, each capable of holding multiple layers of products. As new items are loaded at the top or rear of the lane, the existing items move forward, creating a continuous flow.

Applications

Pallet flow racks find wide applications in various industries where quick access to inventory is crucial:

- Retail and Wholesale: Ideal for managing fast-moving consumer goods, ensuring shelves are always stocked.

- Manufacturing: Useful in assembly lines for parts and components that are needed continuously.

- Cold Storage: Efficient in environments where manual handling is challenging due to temperature conditions.

- Pharmaceuticals and Medical Supplies: Essential for managing perishable or sensitive products that require strict FIFO adherence.

- Distribution Centers: Perfect for sorting and distributing products that need to be shipped quickly.

Installation and Maintenance

Installing Pallet flow racks requires precise planning and execution to ensure the correct inclination and alignment of conveyors or tracks. Regular maintenance, including checking roller function, track alignment, and load capacity, is crucial to maintaining the system's efficiency and safety.

In conclusion, Pallet flow racks offer a highly efficient and practical storage solution for businesses seeking to optimize their inventory management and material handling processes. By leveraging the power of gravity, these racks streamline operations, minimize labor costs, and enhance overall warehouse productivity.